Control Arms, Shafts and Bearing Housings

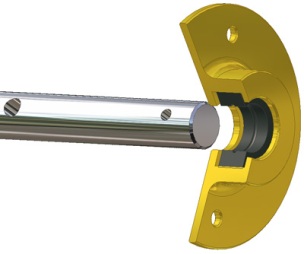

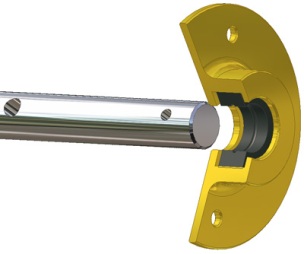

Unique elastomer bearing replaces needle bearing

McFarlane's elastomer bearing is assembled with

tension between the mating surfaces. This tension prevents

micro-movement and its related metal erosion. The bearing contact area

that transfers vibration motion from the heat box to the butterfly shaft

is hundreds of times greater than that of the original needle bearing.

This large surface effectively prevents localized metal erosion.

- Absorbs shaft and butterfly vibration

- Eliminates needle bearing failures

- Increases service life of all components

- Direct replacement for original parts

Proven Design

- Tested to over 700,000 cycles while exposed to avgas, heat and vibration without any change in performance

- Extremely rugged and wear resistant in high temperature and fuel environments

Convenient

- Discontinued part numbers through the factory are now manufactured by McFarlane

- Shafts, arms, bearing housings, monel rivets and roll pins are also available separately or in kits

The carburetor heat box suffer more from engine vibration than other

parts of the engine installation due to the distance of its location

from the center of the engine. Engine vibrations, which are small back

and forth movements of the engine about a point of rotation in the

engine, become larger and more severe as the distance increases from the

center of these movements. A fraction of an inch of engine movement

near the center of the engine could result in over an inch of movement

in an attached component that is located a considerable distance from

the center of the engine. This phenomenon can be visualized by imagining

what would happen if a five foot broom handle was solidly attached to

an idling aircraft engine. The far end of this broom handle would

oscillate wildly back and forth as the engine moved slightly. This is

similar to what is happening to the carburetor heat box. Normal engine

vibrations are amplified by the distance (arm) from the center of the

engine.

Ordinary needle bearings are not well suited for this high vibration

environment as they concentrate the energy of vibration movement to the

very small area where the needles contact the heat box butterfly shaft.

This concentrated kinetic energy results in metal loss and grooves being

worn into the shaft with eventual failure of the bearing system. Needle

bearing failure can lead to ingestion of loose needles into the engine

induction system and cylinders.

Unique elastomer bearing replaces needle bearing